Primary antioxidant 330

|

Product name |

Primary antioxidant 330 |

|

Chemical name |

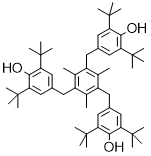

1,3,5-trimethyl-2,4,6-three (3,5-second tert-butyl-4-hydroxybenzyl) benzene;2,4,6-three (3 ', 5' -ditert-butyl-4'-hydroxybenzyl) are trimethyl; |

|

English name |

Antioxidant 330;1,3,5-Trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene |

|

CAS number |

1709-70-2 |

|

Molecular formula |

C54H78O3 |

|

Molecular weight |

775.2 |

|

EINECS Number |

216-971-0 |

|

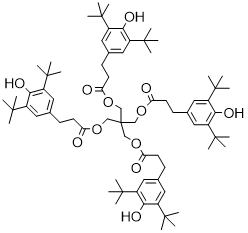

Structural formula |

|

|

Related categories |

antioxidant; plastic additives; functional additives; organic chemical raw materials; |

Melting point: 248-250°C (lit.)Boiling point: 739.54°C (rough estimate) Density 0.8883 (rough estimate) Refractive index: 1.5800 (estimate) Solubility: Almost insoluble in water, soluble in solvents such as benzene, slightly soluble in alcohol solvents. Properties: White to a white-like powder. LogP: 17.17.Stability: stable at normal temperature and pressure to avoid strong oxidant contact.

| Specification | Unit | Standard |

| Appearance | White crystal powder | |

| Main content | % | ≥98.00 |

| Volatiles | % | ≤0.50 |

| Ash content | % | ≤0.10 |

| Melting point | ℃ | ≥240℃ |

It is a kind of high molecular weight hindered phenolic antioxidant, with good compatibility with resin, extraction resistance, low volatilization, high oxygen resistance efficiency and good electrical insulation. It is suitable for oxygen resistance stabilization of various polymers and organic materials, especially with phosphite, thioester, benzofuranone, carbon radical capture agent and other auxiliary antioxidant. In high temperature processing and high extraction resistance applications to give products excellent processing stability and good lasting stability.

Application fields include polyolefin, PET and other thermoplastic polyester and PBT, polyamide, styrene resin and elastomer materials such as polyurethane and natural rubber. Especially suitable for high-temperature processing of polyolefin (such as PP, PE, etc.) pipe, injection molding products, wire and cable and other products processing field. In addition, because it is non-toxic, non-polluting, can maintain a good color of plastic, so it can be used in contact with food packaging materials.

Add amount: generally 0.05% -1.0%, the specific add amount is determined according to the customer application test.

Packed in 20 Kg / 25 Kg kraft paper bag or carton.

Store appropriately in dry, well-ventilated areas below 25 C to avoid contact with ignition sources. The shelf life is two years